Latest News & Trending Topics

Drones in Mining: Everything You Need to Know

In recent years, the use of drones in mining has become increasingly popular. Mining operations require a tremendous amount of resources, including personnel and equipment, to manage and monitor daily movements and project progress.

Drones, also known as Remotely Piloted Aircraft Systems (RPAS) or Unmanned Aerial Vehicles (UAVs), have emerged as a viable solution to improve efficiency, safety and productivity in mining. From surveying mines to monitoring production and providing intelligence in safety compromised situations, drones are proving to be valuable – almost, essential – tools in the mining industry.

Below, we’ll take a look at the use of drones in mining in further detail, informing you everything you need to know. We’ll discuss the different types of drones used by the industry, the advantages of using drones, and highlight some real-life examples of the use of drones in mines around the world.

How UAV and Drone Technology is Influencing Mining Operations

The mining industry is known for high-risk activities that require great attention to safety and efficiency. Activities such as exploration, drilling and blasting require very precise knowledge of geography.

Thanks to drones, we are now able to get a clear picture of dimensions of mines – increasing safety, efficiency, and the effectiveness of data analysis in mine sites.

Drones and Mining: What is a Mine Drone?

A mine drone is an RPAS that is used in mining operations. These drones are typically equipped with cameras and sensors that allow them to capture data and images from the mining site. These include stereo cameras, hyperspectral sensors, infrared sensors and laser range finders.

These drones are operated remotely and can be used to fly over and inspect various areas of a mine, such as stockpiles, haul roads, pit walls and underground tunnels. They are primarily used to collect highly accurate drone data that is used for mapping, surveying, asset inspection and planning purposes.

Can You Fly Drones Over Mines?

The answer is yes, but flying drones is highly regulated. In many countries, it is legal to fly drones over mines if certain rules are followed. These rules may be created by the government and the mine operators themselves.

For example, a drone operator may need to have a license or permit to operate the drone. In Australia, you will need a remote pilot licence if you fly a drone that weighs over 2 kg for hire or reward over someone else’s property.

The drone may also need to be registered with the relevant authorities. In Australia, drone registration with the Civil Aviation Safety Authority (CASA) has been mandatory since mid 2022 for drones that are used for commercial purposes. For safety, mine operators usually only allows contracted operators to fly drones over their mine.

What is a Drone Mining Survey?

A drone mining survey is the process of using drones to collect data and images from mining sites. This data is then analysed to create maps, 3D models and other visual representations that are used to improve the efficiency and safety of mining operations.

The data collected by drones can also be used to identify potential hazards, monitor production and to develop better mine planning strategies.

Drone Applications in Mining

The use of drones in mining operations is becoming increasingly popular due to their versatility and ability to provide real-time data. We’ll discuss this further below.

Why Drones Are Used In Mining?

Some of the most common applications of drones in mining include:

Site Safety Management

Drones can be used to inspect and monitor mining sites, which helps to identify potential safety hazards. This data can be used to develop safety protocols and to prevent accidents before they happen.

Stockpile Management

Drones can also be used to collect data on stockpiles, which helps to monitor inventory levels and prevent shortages. This drone data can also be used to track the movement of materials and to develop better logistics strategies.

Better Inventory and Financial Data

Drones can be used to collect real-time data on the movement of materials and equipment, which helps to improve inventory and financial management. This data can be used to develop better financial models and to identify areas for cost savings.

More And Better Data For Monthly Or Weekly Management

Drones can be used to collect data on a daily or weekly basis, which helps to identify trends and patterns in the mining operation. This data can be used to develop better management strategies and to optimise productivity.

Mine Or Quarry Monitoring And Operation Planning

Drones can be used to monitor and plan mining operations, which helps to improve efficiency and reduce costs. Some specific areas where drones are commonly used include:

Haul Road

Drones can be used to monitor haul roads, which helps to identify potential hazards and improve road maintenance. This data can also be used to optimise traffic flow and reduce congestion.

Water And Sediment Flow

Drones can be used to monitor water and sediment flow, which helps to prevent environmental damage and improve water management. This data can also be used to identify potential flooding hazards and develop better drainage strategies.

Assessment Before And After Drilling Or Blasting

Before and after drilling or blasting activities, drones can be used to inspect the relevant site, identify potential hazards and assess the damage caused. The data collected by the drones can be used to develop better drilling or blasting strategies and ensure that the site is safe for workers to work in.

Hazard Identification And Mitigation

Drones can be used to identify potential hazards such as slope stability issues, rockfall hazards and other geotechnical risks. This data can be used to develop mitigation strategies, involving scaling or meshing, to prevent accidents and improve safety.

Tailings Dams

Tailings dams, for example, are an essential part of mining operations, but they can also pose a significant risk to the environment and local communities if not properly managed.

Drones can be used to monitor tailings dams and identify potential issues, such as leaks or breaches, before they become a problem.

Mining Exploration

Drones can be used to explore and survey mining sites, allowing companies to gather data on the potential resources available. This data can be used to develop better mining strategies and identify areas where exploration efforts should be focused.

Volumetric Monitoring

Drones can be used to monitor stockpiles, waste dumps, and other areas where materials are stored. This data can be used to calculate the volume of materials on site accurately and identify potential issues, such as overloading or shortages.

Processing Plant Inspections

Drones can be used to inspect processing plants and identify potential issues such as equipment failure, corrosion, or leaks. This data can be used to develop maintenance strategies and prevent downtime.

The Use of Drones In Mineral Exploration

Drones can be used to explore and survey mineral deposits, allowing companies to gather data on the potential resources available. This data can be used to develop better mining strategies and identify areas where exploration efforts should be focused.

Data For Better Management

Drones can collect real-time data on mining operations, which can be used to develop better management strategies and optimise productivity. The data collected from drones can also be used to identify areas for cost savings and improve financial management.

Drone Surveys for Mapping & 3D Modelling

Drones can be used to create detailed maps and 3D models of mining sites, allowing companies to visualise the site and identify potential issues before they become a problem.

Advantages Of Using Drones in Mining Sites: What Are The Benefits Of Drones In Mining?

Drones are increasingly being used in mining sites due to the numerous advantages they offer over traditional methods of data collection and monitoring.

Here are some of the advantages of using drones in mining:

Highly Accurate Measurements

Drones can collect high-resolution images and data when flying on-site, allowing for highly accurate measurements of mining sites.

This data can be used to improve the precision of drilling and blasting operations, as well as provide accurate estimates of mineral reserves and stockpile volumes.

Faster And Easily-Repeatable Mining Surveys At Low Cost

Drones can survey mining sites much faster and more efficiently than traditional methods (according to one source, 20 times faster), providing a cost-effective solution for monitoring and mapping.

Additionally, drone surveys can be easily repeated to provide real-time monitoring of mining operations, allowing for more accurate and up-to-date data.

Improving Worker And Site-Safety Management

Drones can be used to monitor mining sites and identify potential safety hazards, such as unstable terrain or equipment failures.

This data can be used to develop safety protocols and prevent accidents, improving worker safety and reducing downtime.

Drones Used For Inspection In Underground Mines

Drones equipped with specialised sensors and cameras can be used for underground inspections in mining sites. This allows for safer inspections of hard-to-reach areas, reducing the risk of injury to workers and improving the accuracy of inspections.

Saving Costs

Drones can significantly reduce the costs of data collection and monitoring in mining operations (according to one source, replacing manner aircraft with drones can reduce survey costs by up to 90%. By providing faster, more efficient, and more accurate data, drones can help reduce the need for expensive equipment, resources and personnel.

Real-Time Monitoring

Drones can provide real-time monitoring of mining sites (i.e. monitoring what is happening on the ground, as it is happening).

This allows companies to quickly identify issues and respond to them before they become a problem. This can help reduce downtime and improve productivity, ultimately leading to cost savings for mining companies.

Accuracy

Drones can collect highly accurate data and images, allowing for better decision-making and more precise mining operations. By providing accurate measurements of stockpile volumes and mineral reserves, drones can help reduce waste ensure they get the most out of their mining operations.

Speed

As mentioned above, drones can survey mining sites faster than other methods reducing the time and resources required for data collection. This can allow for more frequent and efficient monitoring, leading to better decision-making and improved productivity.

Quality and Safety

Businesses operating in mining sites have strict safety regulations they must comply with. By providing accurate and up-to-date data, drones can help ensure that mining operations are conducted safely and efficiently.

This can ultimately lead to improved site safety, reduced downtime, and increased output, ultimately improving the quality of mining operations.

Mapping With Drones Using Photogrammetry: What Kinds of Maps Can You Expect From Mining Drones?

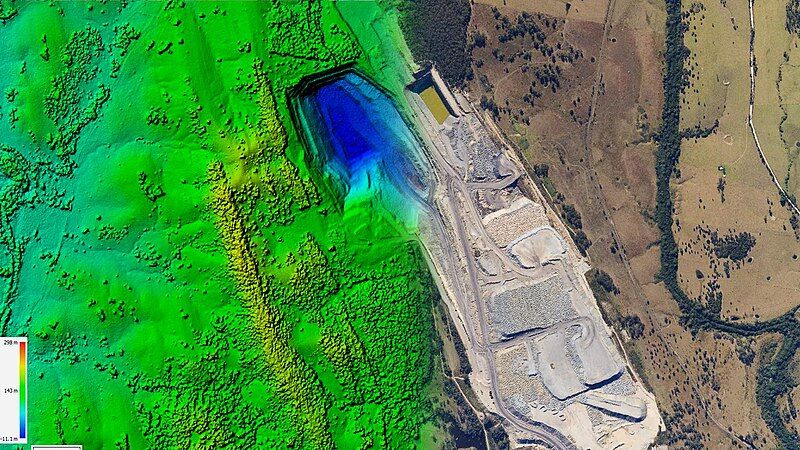

One of the most significant advantages of using drones in mining is their ability to capture accurate and detailed mapping data using photogrammetry techniques.

Below, we will explain the different types of maps you can expect from mining drones and the various types of drones used in the industry.

Orthomosaic Maps, Drone Survey Maps

One of the most common types of maps created using drones in mining is the orthomosaic map. This map is created by stitching together hundreds or thousands of individual aerial photographs taken by a drone (known as orthophotos), creating a single high-resolution image of the entire mining site.

Orthomosaic maps are incredibly useful for monitoring site changes over time and identifying areas of the site that require further investigation or remediation.

Another type of map created using drones is the drone survey map. This map is like an orthomosaic map but is created using more specialised surveying equipment. Drone survey maps are highly accurate and can provide detailed information about the terrain, including contours, elevations and other key data points.

Image credit: Aerutopian, Wikimedia Commons (https://commons.wikimedia.org/wiki/File:Stock_Pile_Reporting.jpg)

3D Point Cloud

Another valuable type of map created using drones is the 3D point cloud. This map is created by capturing a series of overlapping aerial photographs of the site, which are then used to create a highly detailed 3D model of the terrain.

3D point clouds are incredibly useful for identifying areas of the site that are difficult to access or are obscured by vegetation, buildings, or other obstacles.

Digital Terrain Model (DTM)

The digital terrain model (DTM) is another valuable type of map created using drones. This map is similar to a 3D point cloud but is created using more advanced software and equipment. DTM maps are incredibly accurate and can provide detailed information about the terrain, including elevation, slope and other information.

3D Textured Mesh

Finally, the 3D textured mesh is a type of map created using drones that combines the accuracy of a DTM with the visual appeal of an orthomosaic map.

This map provides a high-resolution 3D model of the terrain, complete with textures and colour information that make it easier to interpret and analyse.

What Are The Different Types Of Drones?

Now that we’ve explored the different types of maps created using drones in mining, let’s take a closer look at the different types of drones used in the industry.

Drones To Use In The Mining Industry

The most common types of drones used in the mining industry are Vertical Take-Off and Landing (VTOL) and multi-rotor drones.

VTOL drones are best suited for large-scale mapping projects, such as creating orthomosaic maps or 3D point clouds of mining sites.

Multi-rotor drones, on the other hand, are better suited for smaller-scale mapping projects and asset inspection tasks or monitoring site changes over time.

Drones For Surveying Mines And Quarries

Other mining drones are designed specifically for surveying mines and quarries.

These drones are typically equipped with specialised cameras and sensors that allow them to capture detailed data about the terrain, such as elevation slope, and contours. This data is then used to create accurate maps and models of the site.

Other Mining Drones For Surveying Applications

In addition to VTOL and multi-rotor drones, there are other mining drones designed for specific surveying applications.

For example, there are indoor mine drones that are used to inspect underground tunnels and shafts.

Indoor Mine Drone

Indoor mine drones are designed to fly in enclosed spaces such as underground mines, tunnels, and caves. These drones operate semi-autonomously. They can navigate their way through narrow and obstructed spaces and return to the starting point without operator input. Data can be captured in real time as well as being stored for later analysis.

They are equipped with sensors such as LiDAR, ultrasonic, or optical sensors that can capture high-resolution images and create 3D maps of the area.

VTOL Outdoor Mine Drones

VTOL drones are designed to cover large areas quickly and efficiently. They are usually equipped with GPS and autopilot systems that allow them to fly in a predefined path and capture images along the way. They can take-off and land from small, confined and unprepared areas like a multirotor drone but can cover large areas like a fixed wing drone.

VTOL drones are sometimes larger and more expensive than other types of drones but they can fly faster and cover a larger area in a shorter time. They are commonly used for mapping and surveying large mining sites, stockpiles and haul roads.

Multicopter Outdoor Mine Drone

Multicopter drones, also known as quadcopters or hexacopters, are also used in the mining industry. They are versatile, easy to operate, and can hover in one place for extended times to capture images and data from multiple angles.

Multicopter drones are often equipped with high-resolution cameras and sensors that can capture images and data with a high degree of accuracy and resolution. They are commonly used for mapping, surveying, monitoring, and inspection of mining sites and equipment.

They are generally better for engaging in smaller aerial surveys and inspections (as opposed to VTOL drones, which are better for mine-wide surveys).

Mining Drone Case Studies: What Are Real Applications of Drones In Mining?

Drones have brought a significant change in the mining industry. With the ability to survey mine sites efficiently and accurately, drones have become an essential tool for mining companies.

Below, we will explore some real-world applications of drones in mining through case studies.

Mapping One Of Europe’s Largest Mines

Drones were used to map RTB, the biggest copper mining and smelting complex in Bor, Serbia and one of the largest mines in Europe.

Serbian hardware and software distributor Vekom Geo proposed the use of the VTOL (Vertical Take-off and Landing) mapping drone to RTB. This drone was not only a cost-effective and efficient tool for daily surveying and mapping tasks, but also ensured the safety of the equipment itself.

Vekom Geo was tasked with mapping four mine pits at RTB and providing accurate data allowing RTB to create digital terrain models, calculate waste and ore volumes, monitor mining operations and prepare for future opportunities.

Coal Mining Operation Turns To Drones For Regular Views Of Their Worksite

The Jellinbah Group, which operates an 84 km2 coal mine in Australia, produces about 5 million tons of coking coal each year. Surveys used to be extremely time-consuming and expensive, requiring an entire day for large areas for terrestrial surveys and costing thousands for aircraft surveys.

To reduce costs and increase the accuracy of their surveys, Jellinbah Group integrated VTOL drone technology into their operations. This has resulted in significant time and money savings, with the drone surveys costing only around 10 percent of what the previous methods did.

Africa’s Largest Uranium Mine Surveying

The Rössing Uranium Mine in Namibia, Africa, is one of the largest open-pit uranium mine in the world.

Rocketmine Aerial Data Solutions was contracted by Rössing Uranium, as an exclusive drone services supplier.

To ensure the safety of mining activities and to assist determine areas across the mine for future opportunities, Rössing Uranium used Rocketmine’s drone technology. This allowed the mine to gather the critical data needed to achieve both of these goals.

Drone Surveys Replaced Helicopter Surveys In Quarries

The use of drones in quarry surveying has become increasingly popular due to their efficiency and cost-effectiveness. The aggregates industry, which includes quarries, mines, and pits, is one of the largest users of drones for surveying.

Drones have replaced traditional surveying methods, such as using helicopters, which are expensive and pose a higher safety risk. Drones can capture high-resolution images and create 3D maps of quarries, which help mine operators to identify any issues with the site and plan their operations accordingly.

What Are The Trends Influencing Mining?

Trends in aviation are continuously evolving, and the mining industry is not immune to these changes.

One significant trend that is influencing the mining industry, as explained in this article, is the increased use of drones. Drones are being used to survey mines and monitor the mining processes, providing high-resolution images and data that allow mining companies to make better-informed decisions.

Another trend that is influencing the mining industry is the development of new technologies that enable greater automation and remote control. These technologies allow mining companies to operate more efficiently and cost-effectively. For example, autonomous haul trucks are being used to transport ore from mines, reducing the need for human drivers and improving safety. Similarly, remote-controlled drilling rigs and loaders are being used to extract ore from mines, reducing the risk of accidents and injuries.

Australian Innovation

The mining industry in Australia is at the forefront of utilising advanced technology and methods, with drones being one of the latest exciting innovations being implemented.

The challenging environment of mining, including dangerous terrain, remote locations, and large sites, makes logistics and workflow management difficult. Drones, along with LiDAR and photogrammetry, offer a solution to these challenges by providing accurate and useful data while reducing the risk of exposure to hazards for surveyors and technicians. New applications for these technologies are constantly being developed and tested in the industry.

Flight Safety Foundation Basic Aviation Risk Standard (BARS) audits

The Flight Safety Foundation Basic Aviation Risk Standard (BARS) audits are a set of standards developed to improve aviation safety. BARS audits are used to assess the safety of aviation operations, including those in the mining industry. The audits cover a range of areas, including aircraft maintenance, crew training, and operational procedures.

Mining companies that want to audit their drone operations can use the team at Avlaw for BARS audits. Our experienced auditors have a deep understanding of the mining industry and can provide mining companies with valuable insights into the safety of their drone operations. Through our BARS audits, mining companies can ensure that their drone operations are safe, efficient, and compliant with industry standards.

Get in touch with the team at Avlaw if you require expert advice on the use of drones in your mining operations.